How do you go about creating a straightforward, highly durable design for a spacecraft, one that is readily refuelable and offers manifest advantages for crew comfort and safety? Alex Tolley and Brian McConnell have been asking that question for some time now, coming up with an ingenious solution that could open up large swathes of the Solar System. Alex tells me he is a former computer programmer now serving as a lecturer in biology at the University of California, where he hopes to inspire the next generation of biologists. He’s also a Centauri Dreams regular who was deeply influenced by 2001: A Space Odyssey and the Apollo landings. Below, he fills us in on the details in a narrative that imagines an early trip on such a vessel.

by Alex Tolley

The covered wagon or prairie schooner is one of the iconic images of the 19th century westward migration of the American pioneers. The wagon was simple in construction, very rugged, and repairable. They were powered most often by oxen that lived on the food and water found along the trail. The cost of a wagon, oxen and supplies was about 6 months of family wages.

In 2009 my colleague Brian McConnell and I were thinking about how to open up the exploration of space in an analogous way to the opening up of the American West during the 19th century pioneering era. We were looking for an approach that, like the covered wagon, was affordable, relatively low tech, provided safety in the case of emergencies and the space environment, could “live off the land” for propulsion like oxen, and preferably was reusable so that costs could be amortised over a number of flights.

What follows is a description of the “spacecoach” from the perspective of a new crew member making a first visit to the ship that will be on a Phobos return mission.

Image: ‘Ships of The Plains’ by Samuel Colman.

————————-

Our transfer vehicle docked gently with the Martian Queen airlock. On approach, the Martian Queen resolved into 4 fat sausages, linked end to end. On either side, from bow to stern, were solar PV arrays, partially unfurled. She looked like no spaceship seen since the dawn of the space age.. There was no gleaming metal hull, and she was devoid of all the encrustations of antennae and dishes of those earlier ships. Neither were there any signs of fuel tanks holding liquid cryofuels. Instead, the hull looked dull and somewhat like an old blimp, those non-rigid airships of the early 20th century. The only sign of exterior equipment were those solar PV panels. These were lightweight, moderate performance thin film arrays, extended out on booms to face the sun and drink her rays to power the ship. They looked more like square rigged sails as they fluttered every so gently in the tenuous atmosphere remaining at her orbit.

I knew from the briefing that the Martian Queen needed about 160KW of power, requiring about 800 m2 of arrays at Mars orbit. There was also talk of the next generation “spacecoaches” replacing the PV panels with lightweight rectennas, to convert microwave beams from the orbital transmitters. Most crews didn’t trust that idea yet, but adding a lightweight rectenna was considered a good idea to back up the PVs and also compensate for the lower intensity of sunlight as the newer ships were about to explore Jupiter space. So this was the Martian Queen, the “spacecoach” that would be my home, about to make her 2nd voyage to Phobos.

Following my crew mate Vicki, I passed through the airlock and entered a large space, nearly 60 m3 in volume, shaped like a large cylinder. The interior diameter was about 4.5 meters, about the same as the mothballed Orion I’d seen back at the Cape museum.. But with a length of 10 meters, the volume was 3x larger. The Martian Queen was composed of 4 modules, providing over 200 m3 of full sea level atmosphere pressurized volume, about 2/3rds that of the old Mir space station. Touching the inner skin of the hull it felt flexible, and slightly cool to the touch. A few light taps and the resonant sounds confirmed that there was liquid behind the skin.

Vicki answered my unspoken question about the liquid in the hull. Water was sandwiched between several layers of impermeable Kevlar in the hull. The primary, and ultimately end, use of all the water was for propellant. The spacoach had originally been folded for launch in a standard Falcon 9 fairing. Each module, without any propellant, weighed just 4 tonnes including payload. This was very little and reduced the deadweight mass of the ship. Once in orbit, the interior had been inflated and the hull filled with water. Most of that water had been launched by dumb, low cost boosters, but some was being supplied from extra-terrestrial resources. Supplies from the lunar south pole were becoming increasingly available as Chevron-Petrobras’ Shackleton base was building up mining production. Exploratory vessels were also initiating operations on asteroids, with 24 Themis looking promising with confirmed surface water. In a few decades, it was expected that all water would be supplied from extra-terrestrial sources.

“Why do you put all the water in the hull, rather than in separate tanks?” I asked.

Vicki explained that the water had a number of roles, not just as propellant. The primary reason was radiation protection. The water acted as a good radiation shield, with a halving of the radiation flux with every 18 cm. Starting with about 25 cm of water in the hull, the radiation level inside the module was just 40 percent of that striking the hull. In the event of a major solar flare, the crew could also redirect the water to an interior tube to provide the best radiation shielding for the crew. It looked like that space could get very cozy for the crew, but better than suffering radiation burns.

But it didn’t end there. Micrometeoroids are a rare, but important hazard. The water acted as a shield, absorbing the energy of these grains and preventing penetration inside the hull. The tiny holes in the outer layers quickly heal too. The outer layers of water could be allowed to freeze, trapping a dense forest of fine fibers between the 2 outer fabric layers. This made a strong material, very much like pykrete [1] that offered a stiff outer hull to protect against larger impacts. At Earth’s 1 AU from the sun, reflective foils deployed over the hull allowed passive freezing of the outer layers providing both protection and a large heat sink for the engines.

A noticeable side effect of the hull architecture was the silence. There are no clicks and bangs from thermal heating stresses. Nor did the sunward side of the interior feel noticeably warmer. Thus the water was going to offer very good thermal control of the interior, with pumps in the hull circulating the water providing dynamic thermal control.

Vicki indicated that I should follow her forward to another module. This included the kitchen and dining space. There was a freezer of dried food packages that was being organized by Pieter. Enough for a long trip with a fair variety of meals.

“You seem to have ordered a lot of Boeuf Bourguignon”, joked Pieter.

I wondered when the taste of Boeuf Bourguignon would become rather tiresome after some months. Perhaps more spicy meals like curries would have been more appropriate. I noted that the water supply for rehydrating the food and drinks was connected to the hull too. Of course, I reminded myself, the hull was a huge reservoir of water, effectively inexhaustible are far as the crew was concerned, at least on the outward bound flight.

The facilities were oriented so that “down” was towards the end of the module. This was because during cruise the Martian Queen was going to be rotated, providing some artificial gravity. This made the flight much more comfortable and familiar. We could even eat off regular plates.

Vicki quickly showed me the crew quarters and bathroom in the next module. The inner skin of the hull had been moulded into shapes that could contain water. The baths and showers were also connected to the hull’s water supply. The clean water input was connected to heaters and pumps to the various faucets and shower heads. The grey water from the drains was routed to the main purifier and returned to the hull. I inquired how frequently I could take a shower? Once, twice even three times a week?

“As much as you like”, said Vicki. “There is ample water supply for a single pass through the purifier for all the crew to shower once or twice a day. If the crew is particularly extravagant, even this can be increased with greater recycling. Hygiene is a huge morale booster on these trips.”

The toilet was apparently a composting type, although suitably modified for space. This made sense. The nitrogen and phosphorus was going to be needed for the plants growing in the interior, as well as the Phobos base agricultural areas. Nitrogen and phosphorus were still valuable elements with no rich, off-Earth supplies available. Ducking back into the kitchen space, it was clear that much of the interior was given over to growing plants. They provided the needed psychological connection with Earth, helped recycle the CO2, and freshened the air, removing unpleasant volatiles. The stale, locker room smell of most spaceships was almost absent. Some plants were also growing some fresh foods. I could just imagine the value of a fresh tomato after 6 months of spaceflight!

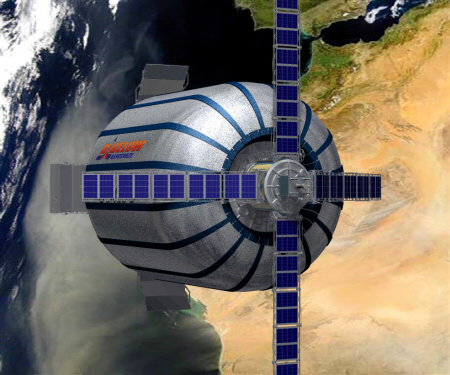

Image: The Genesis 2 space module. An inflatable habitat launched in 2007 and still operational. A design concept similar to the spacecoach. Credit: Bigelow Aerospace (http://www.bigelowaerospace.com).

Image: Inside Bigelow Aerospace Space Station Alpha mockup. This is similar to the spacecoach basic module before addition of specialized fixtures and fittings. Credit: Bigelow Aerospace.

Pulling ourselves back through the leafy interior of the modules, I looked for the engine compartment in the last module. The engines were not obvious on docking, and I wondered where they were. At the rear of the last module, an airlock was currently open, showing an enclosed space beyond. Inside, Hans, the engineer was taking apart one of the engines. He was removing a metal liner from the engine and replacing it with a fresh one. He handed the old one to me and said “carbon deposits”.

I looked closely and saw what he was talking about. Carbon deposition from contaminants in the water supply could build up in the engines, reducing performance. The engines were not much more complex than microwave ovens, although they were fitted with electric grids to further accelerate the microwave heated water plasma.

The exhaust exited via the rear, when the bay doors were opened. Now they were closed, allowing the shirt sleeve repair of the engines. I asked how frequent engine repairs were. Hans informed me that an engine needed some rework after 3-6 hours of operation. The microwave electrothermal engine performance had an Isp of about 800s, although the secondary electric grids could double that by drawing on reserve energy from the solar arrays. Vicki thanked Hans and we drifted back to the main module.

I was a little surprised at the lack of windows, but pleased that there were many flat screens where windows should have been. I looked “out” and saw that I had missed the vernier and maneuvering jets on the hull.

“How are these powered?” I asked Vicki.

“Hydrogen Peroxide, H2O2” she replied.

“Where’s the fuel?”.

“There isn’t any yet. It’s made during the flight. Some of the water in the hull is tapped off, run through that off-the-shelf, standard unit over there. We store the peroxide in hull pockets to wait for the next use. The peroxide engines aren’t very efficient, having an Isp of about 160s, but they provide higher thrust than the main engines and can be used to boost the ship for a faster departure, or land the ship on low gravity worlds with orbital delta-Vs of 0.5 km/s or less. The peroxide has other uses too. It can be decomposed to provide oxygen [3] more quickly than the main ESS electrolyzers, act as an energy store for emergency power [4] and finally as an excellent bactericide to keep the interior clean and remove the bacterial slimes and molds that grow on the inner skin, often in difficult to reach spaces. And before you ask, yes, we have rotating cleaning duties on the Martian Queen.”

So the water in the hull fulfilled a range of uses, before being finally consumed as propellant. Major uses included bathing, direct consumption, rehydrating food, growing plants and, of course, the main oxygen supply. It was converted to peroxide for the high thrust engines, for energy storage and for another emergency O2 supply.

“Vicki, a quick mental calculation seems to come up short on the water requirement for the flight. Is what I see all that is needed?”

Vicki smiled: “The impact of using water as propellant on performance is significant. The total water budget for the trip is about 4 times the total mass of the ship and payload, compared to about 14 times for a conventional liquid hydrogen and LOX chemical rocket, primarily because of the higher Isp of the electrothermal engines. But the low hull mass and reduced consumables payload reduces the main mass of the the Martian Queen allowing a much smaller, more efficient spaceship. She is also a lot roomier, more comfortable and much safer. An Apollo 13 type accident would not be survivable in a conventional ship, but we have very large reserves of consumables and oxygen for the crew to survive until a rescue or the return trajectory was complete. In addition, even without water supplies at Phobos, the baseline mission cost to Phobos and return is on the order of a $100m dollars. That is why your institution can afford to pay for your slot on this mission. Reusability of the Martian Queen for multiple missions, fresh water at Phobos, and better performing solar panels and electric engines will eventually reduce that cost perhaps another order of magnitude.”

I pondered that for a moment. While not a cheap solution for interplanetary travel, it put the cost well within the realm of the super-rich and wealthy institutions. A mere decade earlier, a simple lunar flyby and return in an adapted Soyuz craft was priced at around $100m per passenger by Space Adventures. Spaceflight was definitely getting cheaper and safer.

————————-

If interplanetary travel is initially based around the design concepts of water propellant craft, then the economics and infrastructure requirements will be dependent on available supplies of water already in space at suitable locations for fuel dumps. Bodies that may harbor economically useful quantities of accessible water include the moon (shadowed polar regions), water rich asteroids and dead comets. A tantalizing possibility is Ceres, that Dawn is expected to rendezvous with this year (2015). Ceres is expected to have prodigious quantities of frozen water, possibly even a subsurface ocean. A mining operation to extract pure water from the brew of ice and chemicals might offer the opportunity to open up the inner solar solar system. Once at Jupiter, the icy moons offer an almost inexhaustible supply of water.

References

1. Pykrete http://en.wikipedia.org/wiki/Pykrete

2. Bigelow Aerospace B330 http://bigelowaerospace.com/b330/

3. 47kg O2/1000 kg H2O2 (10%)

4. ~2 MJ, kg.

5. J E Brandenburg, J Kline and D Sullivan, “The microwave electro-thermal (MET) thruster using water vapor propellant,” Plasma Science, IEEE Transactions on (Volume:33, Issue:2) pp 776-782 (2005).

6. E. Wernimont, M. Ventura, G. Garboden and P. Mullens. “Past and Present Uses of Rocket Grade Hydrogen Peroxide”, http://www.hydrogen-peroxide.us/history-US-General-Kinetics/H2O2_Conf_1999-Past_Present_Uses_of_Rocket_Grade_Hydrogen_Peroxide.pdf

Trackbacks/Pingbacks