It’s interesting to contemplate the kind of missions we could fly if we develop lightweight smallsats coupled with solar sails, deploying them in Sundiver maneuvers to boost their acceleration. Getting past Voyager 1’s 17.1 kilometers per second would itself be a headline accomplishment, demonstrating the feasibility of this kind of maneuver for boosting delta-v as the spacecraft closes to perhaps 0.2 AU of the Sun before adjusting sail attitude to get maximum acceleration from solar photons.

The economic case for smallsats and sails is apparent. Consider The Planetary Society’s LightSail-2, a solar sail in low Earth orbit, which demonstrated its ability to operate and change its orbit in space for multiple years before reentering Earth’s atmosphere in November of 2022. Launched in 2018, LightSail-2 cost $7 million. NASA’s Solar Cruiser, a much larger design still in development despite budging hiccups, weighs in at $65 million. Slava Turyshev and team at the Jet Propulsion Laboratory independently verified a cost model, with the help of Aerospace Corporation, of $11 million for a one-year interplanetary flight based on their Technology Demonstrator design.

Those numbers go up with the complexity of the mission, but can be reduced if we take advantage of the fact that spacecraft like these can be repurposed. A string of smallsat sailcraft sent, for example, to Uranus to conduct flybys of the planet, its moons and rings, would benefit from economies of scale, with successive missions to other outer system targets costing less than the ones that preceded them. Here the contrast between dedicated flagship missions (think Cassini or the Decadal Suevey’s projected Uranus Orbiter) could not be greater. Instead of a separately developed spacecraft for each destination, the modular smallsat/sail model creates a base platform allowing fast, low-cost missions throughout the Solar System.

To the objection that we need orbiters at places like Uranus to get the best science, the answer can only be that we need both kinds of mission if we are not to bog down in high-stakes financial commitments that preclude targets for decades at a time. Of course we need orbiters. But in between, the list of targets for fast flybys is long, and let’s not forget the extraordinary range of data returned by New Horizons at Pluto/Charon and beyond. As the authors of the recent paper from the JPL team note, heliophysics can benefit from missions sent to various directions in the heliosphere:

The shape of the heliosphere and the extent of its tail are subject to debate and the new model of the heliosphere—roughly spherical with a radius of ?100 AU—needs confirmation. Of course, every mission out to >100 AU will test it, but a series of paired missions (nose and tail, and in perpendicular directions) would provide a substantial improvement in our understanding of ISM/solar wind interactions and dynamics. High-velocity, low-cost sailcraft could probe these questions related to the transition region from local to pristine ISM sooner and at lower cost than competing mission concepts. Since the exact trajectory is not that crucial, this would also provide excellent opportunities for ad hoc trans-Neptunian object flybys.

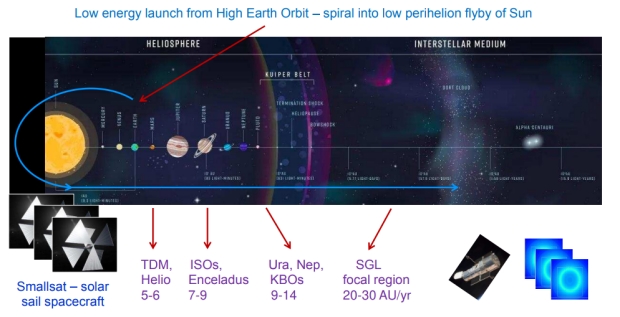

Image: This is Figure 5 from the paper. Caption: New paradigm – fast, low-cost, interplanetary sailcraft with trajectories unconstrained to the ecliptic plane. Note the capability development phases from TDM (at 5–6 AU/yr) to the mission to the focal region of the SGL (20–30 AU/yr). Credit: Turyshev et al.

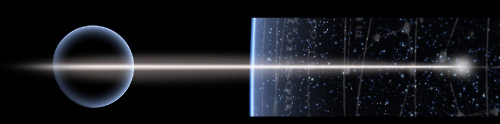

What I see emerging, however, is a new model not just for flyby missions but for the kind of complicated mission we’ve gotten so much out of through spacecraft like Cassini. We are on the cusp of the era of robotic self-assembly, which means we can usefully combine these ideas. Ten fast smallsats capable of flying considerably faster than anything we’ve flown before can, in this vision, self-assemble into one or more larger craft enroute to a particular destination. The Solar Gravitational Lens mission as designed at JPL relies on self-assembly to achieve the needed payload mass and also draws on the ability of smallsats with sails to achieve the needed acceleration.

We can trace robotic self-assembly all the way back to John von Neumann’s self-replicating probes, but as far as I know, it was Robert Freitas who in 1980 first took the idea apart in terms of a serious engineering study. Freitas applied self-assembly to a highly modified probe based on the Project Daedalus craft. Freeman Dyson considered robotic methods using robot swarms to build large structures and also proposed his famous ‘Astrochicken,’ a 1 kg self-replicating automaton that was part biological and was conceived as a way of exploring the Solar System. Eric Drexler is well known for positing nanomachines that could build large structures in space.

So the idea has an interesting past, and now we can consider the Turyshev paper we’ve been looking at in these past few posts as the outline of an overall rethinking of the classic one-destination-per-mission concept, one that allows cheap flybys but also alternate ways of putting larger instrumented craft into the kind of orbits the 2022 Decadal has recommended for its putative Uranus mission. Modular smallsat design might incorporate self-assembly including propulsion modules for slowing the encounter speed of a mission to the outer planets. Here is what the paper says on the topic as it relates to a possible mission to search for life in the plumes of Enceladus:

Another mission type may rely on in-flight aggregation [8], which may be needed to allow for orbital capture. For that, after perihelion passage and while moving at 5 AU/yr (?25 km/s), the microsats would perform inflight aggregation to make a fully capable smallsat to satisfy conditions for in situ investigations. One such important capability may be enhanced on-board propulsion capable of providing the ?v needed to slow down the smallsat. In this case, before approaching Enceladus, the spacecraft reduces its velocity by 7.5 km/s using a combination of on-board propulsion and gravity assists. Moving in the same direction with Enceladus (which orbits Saturn at 12.6 km/s) it achieves the conditions for in situ biomaterial collection.

We might, then, consider the option of either multiple flybys of small probes or larger payloads in self-assembling smallsat craft of the ice giants and other targets in the outer reaches of the system. The paper names quite a few possibilities. Among them:

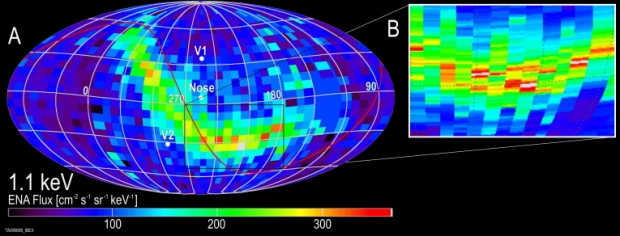

The so-called ‘interstellar ribbon,’ evidently determined by interactions between the heliosphere and the local interstellar magnetic field.

Indirect probing of sailcraft trajectory in search of information about the putative Planet 9 and its gravitational effects somewhere between 300 and 500 AU of the Sun (Breakthrough Starshot has also discussed this). And if Planet 9 is found, target missions to a world much too far away to study with chemical propulsion methods.

The Kuiper Belt and beyond: KBOs and dwarf planets like Haumea, Makemake, Eris, and Quaoar within roughly 100 AU of the Sun, or even Sedna, whose orbit takes it well beyond 100 AU.

Observations of Earth as exoplanet, observing its transits across the Sun and improving transit spectroscopy.

Missions to interstellar objects like 1/I ‘Oumuamua, which are believed to occur in substantial numbers and likely to be a rich field for future discovery.

Studies of the local interplanetary dust cloud responsible for the zodiacal light.

Exoplanet imaging through self-assembling smallsats, the JPL Solar Gravitational Lens mission.

Image: This is Figure 9 from the paper. Caption: IBEX ENA Ribbon. A closer look suggests that the numbers of ENAs are enhanced at the interstellar boundary. A Sundiver spacecraft will go through this boundary as it travels to the ISM. Credit: SwRI.

As examined in JPL’s Phase III study for the SGL mission (the term ‘microsat’ below refers to that category of smallsats massing less than 20 kilograms):

The in-flight (as opposed to Earth-orbiting or cislunar) autonomous assembly [8] allows us to build large spacecraft from modules, separately delivered in the form of microsats (<20 kg), where each microsat is placed on a fast solar system transit trajectory via solar sail propulsion to velocities of ?10 AU/yr. Such a modular approach of combining various microsats into one larger spacecraft for a deep space mission is innovative and will be matured as part of the TDM flights. This unexplored concept overcomes the size and mass limits of typical solar sail missions. Autonomous docking and in-flight assembly are done after a large ?v maneuver, i.e., after passing through perihelion. The concept also offers the compelling ability to assemble different types of instruments and components in a modular fashion, to accomplish many different mission types.

To say that robotic assembly is an ‘unexplored concept’ underlines how much would have to be resolved to make such a daring mission work. The paper goes into more details, of which I’ll mention the high accuracy demanded in terms of trajectory. Remember, we’re talking about flinging each microsat into the outer system after perihelion on its own, with the need for successful rendezvous and assembly not in Earth orbit but in outbound cruise. Docking technologies for structural, power and data connections would go far beyond those deployed on any missions flown to date.

Even so, I’m persuaded this concept is feasible. It’s also completely brilliant.

Autonomous in-space docking has been demonstrated, while proximity operation technologies specific to such missions can be developed with time. I’ve referred before in these pages to NASA’s On-Orbit Autonomous Assembly from Nanosatellites (OAAN) project, and note that the agency has followed with a CubeSat Proximity Operations Demonstration (CPOD) mission. Needless to say, we’ll keep an eye on these and other efforts. I’m reminded of the intricacies of JWST deployment and have to say that from this layman’s view, we are building the roadmap to make self-assembly happen.

Image: An early artist’s impression of OAAN. Credit: NASA.

Alex Tolley has been looking at self-assembly issues in the comments to the previous post. I highly recommend reading what he has to say. I noted this about redundancy, an issue I hadn’t considered. Quoting Alex:

“Normally, a swarm of independent probe sails would offer redundancy in case of failure. A swarm of flyby sail probes can afford the odd failure. However, this is not the case with probes that must be combined into a functioning whole. Now we have a weakest link problem. Any failure could jeopardize the mission if a failed probe has a crucial component needed for the final combined probes. That failure could be with the payload, or with the sail system itself. A sail may fail with a malfunctioning blade, which prevents being able to rendezvous with the rest of the swarm, or more subtly, be unable to manage fine maneuvering for docking.”

Self-assembly is complex indeed, making early missions that can demonstrate docking and assembly a priority. Success could re-shape how we conceive deep space missions.

For a more detailed look at how the JPL team views self-assembly in the context of the SGL mission, see Helvajian et al., “A mission architecture to reach and operate at the focal region of the solar gravitational lens” (abstract). The Turyshev et al. paper is “Science opportunities with solar sailing smallsats,” available as a preprint. I’ve also written about self-assembly in Solar Gravitational Lens: Sailcraft and In-Flight Assembly.

Thinking about Starshot I had wondered about self-assembly for the nano-craft at destination, which would be Proxima Centauri. Maybe it was thought of? A set of ‘chip-ships’ huddle in approach and assemble an ‘antenna-transmitter’ for communications back to Earth. Maybe this Com-vehicle assembles into a ‘radiation pressure brake’? I really don’t know how big a brake ‘sail’ one would need to go into orbit at Proxima or make a slow encounter. Stopping at Proxima when going 20% the speed of light has always been a tough problem.

It is interesting to think that a object too massive to boost to 20 percent the speed of like might be busted into to bits which can be, at destination, re- accumulated.

Or something along those lines.

Great ideas

CubeSat docking.

In 2014, NASA selected Cornell to collaborate on a docking program. The PR piece :

Cubesat Proximity Operations Demonstration

NASA Partners with Leading Technology Innovators to Enable Future Exploration

These 2 papers were produced:

Autonomous Rendezvous and Docking of Two 3U Cubesats Using a Novel Permanent-Magnet Docking Mechanism

PRELIMINARY GN&C DESIGN FOR THE ON-ORBIT AUTONOMOUS ASSEMBLY OF NANOSATELLITE DEMONSTRATION MISSION

The idea was to show that 2 separated CubeSats could use positioning systems to orientate themselves and use cold gas thrusters to close in on each other. A magnetic docking mechanism was used to connect the 2 CubeSats. IDK if the mission was launched and the lab system tested in space (LEO). If successful, the idea was to try docking multiple CubeSats.

I have not found any progress since then, nor does there seem to be any mention on NASA’s website with a fairly cursory search.

In terms of the deep space missions, it now seems clear that the solar sails would have to bring their payloads within perhaps 10,000 km of each other. The sails would be discarded and teh payloads self-propel themselves to rendezvous and docking. This would have to be a far more sophisticated docking than just having 2 magnets hold the craft together, although conceivably communications might be achieved with some em system like WiFi or Bluetooth. Power would need to be physically connected unless each unit was fully self-powered.

In summary, the idea of self-assembly, especially to lower costs and simplify the construction of the solar sails is a great idea, but the technology to achieve docking needs a lot of development and could be high risk.

If the issue is reducing sail size to an easily manufacturable and deployable size, why not simply find a way to harness the sails to the already integrated payload? I envision this like a team of horses side by side pulling a chariot. With a long enough tether to prevent sails from shading each other, the sails could be harnessed in series, like a dog sled or coach and horses. While the harness is a parasitic mass, and tether deployment not-risk free, the benefit is that all the probe systems can be fully integrated and working, and no self-propulsion, rendezvous, and dock masses are needed.

Always glad to see lightsail propulsion discussed here at Centauri Dreams, including the fairly recent June 7, 2022, discussion of diffractive sails.

Lightsailing has the potential to be a most disruptive propulsion technology, in terms of the wide of array of missions that it then opens up.

This new paper once again (re)presents many of those possible missions, including the not-quite-new-under-the-Sun Sundiver concept.

But the devil, as always, is in the details, in terms of maturing sundry directly or indirectly related technologies . . . .

Ideally, an at least initial technology demonstration mission (TDM) to fully mature the lightsail propulsion technology itself would isolate on the maturing of only that technology itself – without requiring the substantial maturing of also a number of other technologies for mission success.

Along the lines of Alex’s comments here and previously, I’m not sanguine, FWIW, about the at least immediate prospects for self-assembly post-perihelion (for later phase missions).

I don’t see how you mate up a number of smallsats without having cold gas thruster reaction control systems (RCS) on the sundry smallsats. In at least my lay mind’s eye – from a childhood watching Gemini and Apollo dockings – I have this image of multiple RCS rockets firing in multiple different axes in rapid succession to line up two spacecraft to achieve a successful docking.

. . . for each and every such docking procedure of multiple docking procedures required to assemble an overall spacecraft post-perihelion.

That sounds to me like: (a) there will be a relatively high level of difficulty in reliably achieving that with multiple smallsats on post-perihelion trajectories; and (b) there will be a perhaps substantial – especially aggregate – mass penalty to having the requisite RCS systems (including fuel, power, and computing) on board the sundry smallsats to achieve those multiple dockings.

Including when, e.g., the sundry multiple post-perihelion trajectories don’t quite line up according to plan and additional burns have to be made to get the craft within the planned pre-docking distance. If the scaled-down RCS systems can handle only perfectly aligned trajectories – after multiple independent close passes to a somewhat volatile and not-yet-fully-understood star – then they’re not going to be much use. So those systems perhaps will need to be more robust – and thus have more combined mass – than the systems otherwise theoretically required on paper for perfectly-aligned trajectories.

(I’ll come back to that mass penalty point below.)

I suggest a possible different tack in the overall multi-year (and phased missions) strategy: in-space manufacturing of the sail vanes.

Yes, yes, the technology readiness level (TRL) of in-space manufacturing is – also – very low.

But consider what we end up with – in the specific context of lightsailing – by focusing on maturing the TRL instead of in-space manufacturing of the sail vanes.

We end up with (a) the ability to utilize sail vanes that are not size-constrained by the need to be stowable for launch and then deployable in space from the stowed configuration; and (b) underlying sail materials that are not design-constrained by having to have the robustness, etc. to be so stowed and then deployed. And we do that while (c) dispensing with any mass associated with stowing and deploying sails to satisfy launch constraints that have little or nothing to do with the functioning of the sails in space.

Sail material development is where the rubber figuratively meets the road for lightsailing. Throughout this paper, the authors speak in regard to later phase missions in terms of what sail material is projected . . . to be . . . able to do. Sail material development is what enables a large number of the later-phase missions described in the paper to happen . . . or not, as the development discussed is only projected, not yet fully realized.

In-space manufacturing eliminates a substantial design constraint attending stowing and deploying that does not otherwise directly relate to the functioning then of the sail material in space. Imagine if sail material researchers could focus only on the propulsion-to-weight potential of a potential sail material as opposed to having to also be concerned with whether the material also was capable of being stowed for launch and then deployed with booms, etc. (Although the capability to be reliably manufactured in space of course would then become a design constraint in and of itself.)

Ultimately, the best approach to lightsailing likely will be fabricating the sail vanes in space and then mating up the individual sail vanes to the individual sail-vane control actuator units on a spacecraft bus (at least initially) launched from Earth.

With in-space sail vane manufacture, we could mate the parts (the bus and sail vanes) together in the lightcraft’s final mission configuration – with the use of either a robotic arm attached with the fab unit and/or small reusable space tugs – in high Earth orbit before the lightcraft then falls inward within the solar system toward the Sun for the Sundiver manouver.

“Just” launch the desired spacecraft bus to the high Earth orbit assembly point, attach the requisite sail vanes for that mission, and then start the in-bound journey using the sails to achieve the in-bound trajectory. (Possibly also with a boost from an expendable space tug also parked at high Earth orbit at the assembly point.)

Smallsats, swarms, flybys and all that no doubt have their place, particularly with interstellar missions flying at a meaningful fraction of the speed of light.

And the post-perihelion assembly suggestion by the authors itself reinforces the point that there are practical limits on the missions that can be achieved with smallsats if/when launched as a unitary stand-alone spacecraft.

In-space manufacturing of sail vanes instead provides much greater ultimate flexibility with respect to lightsailing and associated spacecraft bus mass and design.

Particularly with respect to intra-solar system missions where (a) a greater mass bus may be desirable and conceivable for sundry science tasks, but (b) we’re inherently not talking about decelerating from a substantial fraction of light speed in order to achieve something more than a flyby.

And particularly with respect to orbital insertion for intra-system gas giant missions.

I’m definitely a layperson with regard to orbital dynamics. And, in that vein, I have a couple of lay questions.

Isn’t it at least conceivable to match (a) the – ultimate – hyperbolic escape velocity achieved by a lightcraft after perihelion with (b) very roughly, the velocity required at orbital insertion at a particular gas giant (also taking into account the gravitational acceleration as the craft approaches the gas giant)?

In that regard, I note that the at least escape velocities for the sundry gas giants are roughly in the range of some of the post-perihelion hyperbolic escape velocities discussed in the paper. That leads at least my lay mind to the prospect of roughly matching the post-perihelion velocity (determined by the sail material and the closeness of perihelion) to the desired velocity at orbital insertion of the gas giant (allowing also for that gravitational acceleration on approach).

I’m assuming that for a lightsail craft, the problem then is that – even if you do that – you then can’t do the corrections necessary to finetune the trajectory and velocity for an actually successful orbital insertion (and any needed subsequent orbital adjustments). That is, a lightsail craft just doesn’t have that fine-tuning course/velocity correction capacity at 5 or more AU out.

But . . . could we then include a low mass chemical propulsion unit with the lightcraft bus to be held in reserve specifically for those orbital insertion course correction burns?

Yes, chemical propulsion units (and propellant) have a mass penalty (now getting back to that). But we’re talking about an otherwise exceedingly low mass craft and strictly the course correction burns required for orbital insertion of the possibly still – relatively – low mass craft (even after this add-on). The actual propulsion unit required perhaps would be much more low mass than a single reaction control system (RCS) unit used on a much higher mass craft. (Or, at least that’s the nut of my question, anyway.)

If we’re figuratively going to “strap on” some sort of chemical propulsion unit to a lightcraft bus, with the associated mass penalty, it would be preferable – all things otherwise being equal, if that is possible – to take on that type of mass penalty to actually achieve orbital insertion at a gas giant as opposed to “spending” that mass penalty instead on a number of RCS systems that are needed simply to put the finished craft together . . . and then only for a flyby mission.

So, if we’re going to start from a low TRL point – post-perihelion assembly of smallsats on the one hand and in-space manufacturing of sail vanes on the other – I would put my figurative money on the latter. In-space manufacturing of sail vanes arguably potentially (a) allows the most flexibility in spacecraft bus design and mass and (b) produces the most reliably versatile lightcraft in space.

But in the interim, the initial TDM of course needs to be stripped down to the absolute bare minimum configuration required to show that the sail material can survive perihelion and then come out, as I say, like a screamin’ demon on the other side. More Wright Flyer than 747 in terms of overall capability. With “no (post-perihelion) assembly required,” which of course is a later-phase mission concept in the paper.

Much of the rest of the paper perhaps puts a lot of very imaginative cart before that stripped-down initial-TDM horse – although there undeniably is the practical need to entice funding agencies to start down the path in the first instance.

But the initial TDM of course should be as bare bones as possible. And the very first TDM (and post-perihelion assembly again is a later-phase mission concept) should isolate maturing the sail propulsion technology as much as possible without also taking on maturing other technologies as well, to the extent possible.

As a follow-up note, there certainly are a “few” hurdles to clear in achieving in-space manufacturing of sail vanes, as with any technology requiring maturing – including of course also post-perihelion self-assembly of smallsats.

However, that sort of manufacturing technology is not necessarily in the realm of merely science fiction or only a far off circa 22nd Century technology.

For example, one of the likely initial subjects of in-space manufacturing will be more expansive and lightweight solar panels for use in space.

See Wikipedia: “Space Manufacturing, Products.” https://en.wikipedia.org/wiki/Space_manufacturing

I submit that it’s not that big of a jump in terms of processes, etc. to similarly make more expansive and lightweight sail vanes in space through similar manufacturing strategies.

Fairly serious private companies already are actively seeking to enter the in-space manufacturing, uh, space.

See, e.g., Wikipedia: “Axiom Space.”

https://en.wikipedia.org/wiki/Axiom_Space

But you want something (at least somewhat) closer to fruition?

OK, consider the SpaceX Starship. Elon Musk was talking about ultimately bringing per-launch costs down initially to around $7 million and then later around $2 million.

See Wikipedia: “Space Launch Market Competition, 2014 and Beyond.”

https://en.wikipedia.org/wiki/Space_launch_market_competition

That may not be as cheap as a launch rideshare, but it’s a far, far cry from the around $60 million per-launch cost of other launch vehicles. And, most critically, that would keep the overall mission cost of a larger-than-smallsat lightcraft – even with a standalone launch – well below other NASA deeper space missions that employ primarily chemical propulsion once in space. (All assuming that Musk can follow through on these particular launch-cost claims once the Starship is fully matured, both of which remain to be seen.)

The projected cargo space for the Starship has been reported to be capable of fitting “objects that are up to 72 feet in length and 26 feet wide.”

V. Tangermann, “Here’s How Many Shipping Containers You Could Fit in the SpaceX’s Starship,” Futurism (June 30, 2020); https://futurism.com/shipping-containers-fit-inside-spacex-starship

That’s a lot of space to fit a craft’s sail vanes or – if you must – to fold and stow sail material for even larger deployed sail vanes in space. Or to launch a boatload of completed fairly large sail vanes to be mated up in space later with special-purpose spacecraft buses launched separately from earth (including via rideshare) – which initially gets around the current relatively low TRL of in-space manufacturing. All with a relatively inexpensive launch cost for the lightcraft or associated material (completed vanes) launched via the Starship. (Assuming that that light of a high-volume-but-low-mass cargo load wouldn’t prohibitively throw off the balance required for the overall launch vehicle.)

For example, one could have a simple square spacecraft bus with sail vanes and their control actuators attached to each one of the four sides of the bus.

To configure for launch: (1) “fan-in” each sail vane; (2) use each actuator to fold, at the point where the vane and actuator are linked to the bus, the entire “fanned-in” vane forward on the craft (i.e. in the direction that will face the sun at perihelion); and (3) secure, inter alia, the aft of the craft (the side to face away from the sun) to the bottom of the cargo bay (i.e., with the folded vanes pointing up in the cargo bay at launch).

Then, once deployed in space, the vanes “simply” are folded back to level with the plane of the forward surface of the bus and they are fanned out to create an overall cruciform deployed sail surface, composed of four independently maneuverable vanes.

Once the sail vanes are used to initiate the inward trajectory toward the Sun, they then can be turned edge-on to the Sun on the inbound journey until they are turned face-on again at perihelion.

As best as I can tell per an online calculator, an equilateral triangle with an approximate height of 72′ has an area of approximately 278 square meters, and we’re talking about four such vanes in this example. That area compares favorably to the 120 square meter total sail vane area in the initial-phase design discussed in the paper.

(With perhaps also sail-vane “warping” – a control surface strategy employed by the Wright brothers – in addition to independent tilting/rotating of the vanes, one even conceivably could create a “pinwheel” effect to initiate a spin of the craft if desired for one reason or another.)

(With this simple bus design, thermal management would involve shielding the forward side of the spacecraft bus – and likely also the actuators – and then keeping the vulnerable components of the bus, etc. in the shadow of that forward shielding similar conceptually to the strategy employed by the Parker Solar Probe. Unless such a simpler initial cruciform lightcraft design simply is not sufficiently stable for some reason, it seems like it’s not “as heavy of a lift” metaphorically in terms of addressing design concerns such as thermal management. All else being equal, simpler would seem to be better when isolating a technology – such as lightsail propulsion for a Sundiver concept – for a TDM. A very scaled-down version of the simple design conceivably could be secured in the configuration described above at the very forward part of a launch faring in a rideshare context for an initial TDM.)

Anyway – basic point being – there are potential alternative strategies (discussed both here and elsewhere in the comments to Paul’s article) for launching ultimately-larger-than-smallsat lightcraft for later-phase deep space missions that serve as alternatives to the post-perihelion self-assembly strategy very preliminarily explored by the authors of the paper.

The authors understandably deeply pursue the overall concept of mating smallsats with lightsails – that’s after all what they’re writing about – to see how far that strategy potentially could go. And they get over the “hump” of a need eventually for larger-mass (aggregate) spacecraft – that then can do more – by using the post-perihelion self-assembly strategy.

I’m just saying that that is not the only possible strategy to get over that design “hump” once the TRL of the underlying sail propulsion technology (for a Sundiver concept) is itself fully matured in the initial phases that they outline in their paper.

Again, I understand the need to entice funding agencies and to thus present a proposal that can achieve significant science down the line. But post-perihelion self-assembly is not necessarily the only strategy that can or should be considered for achieving larger mass and greater capability lightcraft (whether as unitary or aggregate craft).

I believe that lightcraft missions represent the future – and not a necessarily distant one – for so many types of missions where lightcraft propulsion in principle is the superior (and sometimes only viable) in-space propulsion technology. We’re talking now not about “if” but instead “how” on certain associated mission details.

That’s good progress.

And I’m heartened to hear that the so very critical sail material research is ongoing, for both reflective and diffractive sail materials.

I’m definitely with you on in-space manufacture. Eric Drexker, when he was pushing solar sails, expected to go this route, with deposition onto a surface that could be easily removed, perhaps something like wax that could be boiled off. He had sail material made on Earth this way that he claimed would literally rise up on warm air in a room. In practice, I suspect such material would be integrated with a mesh, perhaps graphene or carbon nanotubes, to create a strong, rip-stop type of low-areal-density sail material that would be attached to the spars of the desired design.

This is the sort of experimental manufacturing that could be tested in an enclosed site attached to the ISS or similar space station. If it worked and proved cost-effective, these sails could be immense, like those Robert Forward assumed for crewed interstellar ships.

Sails needn’t just run before the wind as assumed with hyperbolic flights towards the edge of the solar system. If following a more parabolic orbit, or even better, a slow spiral, the sail can both accelerate and decelerate depending on sail orientation towards the sun. Cargo payloads both outwards and inwards can be “flown” using this approach. Unlike spacecraft using rocket propulsion, they can both orbit planets and be statutes, balancing gravitational attraction towards the surface with sunlight on the sail counteracting that force.

I recall Drexler talking about 1-ton payloads for the sails of his design.

As regards production, I would envisage the sail material made rather like cloth, a continuous process but with the sail immediately attached to the supporting spars as it could not be rolled up. A robot would do the attachment and manage the joining of material strips to each other to make the desired sail shape and area. It is a pity that after 40 years, space manufacture of large items has not progressed very much, perhaps for purely commercial reasons. Do we need a good commercial reason to build such large sails to deliver space probes and recover extracted materials?

You want sails to be as broad as possible.

One subject should be how to make very wide sails.

I don’t think vertical manufacturing has been looked at.

A warehouse can only be made so wide…but a slit in the Earth—-maybe along a fault…can be as deep as you please…lined with bricks to either side. The sail comes out of this slit on rollers and placed on parallel trail tracks to be slid into rocket fairings.

In space, the ends can be bonded with something like dual ISS trusses.

Not sure physical assembly is really the way to go, a swarm connected through a Bluetooth/WiFi ‘local-network’ system could do better with less points of failure. (Also easier to have redundancy but having elements that can do double duty)

If we look at systems like the square kilometre array, they no assembled but part of a network, making the sum greater then it’s parts. Something similar can be achieved with these types of missions.

I’d think the most desirable trait in a solar sail should be a precisely controlled shape. The images I’ve seen from space look more like reused aluminum foil, but imagine if an SGL probe had a surface so smooth and predictably curved that it could be used as the reflector of a space telescope. A small group might measure one SGL pixel, or more might work together as a spotting scope in other directions. They could also be used to concentrate very distant sunlight onto small solar collectors.

Laser or microwave beams might be used to measure inter-probe distances ( https://phys.org/news/2023-04-team-quantum-enhanced-microwave-ranging.html ). “Optical tweezers” can be used to manipulate probes. ( https://en.wikipedia.org/wiki/Optical_tweezers ) Such EM beams could simultaneously host communications channels, and might work as a sort of power bus between satellites, just as microwave satellites have been proposed to bring solar power to Earth.

If the satellites have synchronized time and know and can control their spacing, they ought to be able to broadcast as a phased array, sending signals in any arbitrary direction without moving like a 5G cell phone antenna.

If a few satellites have electron guns powered by the others working in unison, and aim them back at the others to apply charge, could they create an electric sail effect to move more laterally or brake at the heliopause?